Thin Carbon Fiber Sheets 0.2mm 0.3mm

Basic Info

| Model NO. | large carbon fiber sheets |

| Brand | Sw Carbon Fiber Sheet 0.25 |

| Feature | Carbon Fiber Heat Resistant Sheet |

| Surface | Twill/Plain/Forged/Glossy/Matte |

| Technology | High Strength |

| Size | Custom |

| MOQ | 10PCS |

| Quality | High Strength Durable |

| Weight | Lightweight |

| Color | Black/Custom |

| Transport Package | Carton 3K Carbon Fiber Sheet |

| Specification | custom size |

| Trademark | SW 3k carbon fiber sheet |

| Origin | China, Weihai |

| Production Capacity | 10000/Month |

Product Description

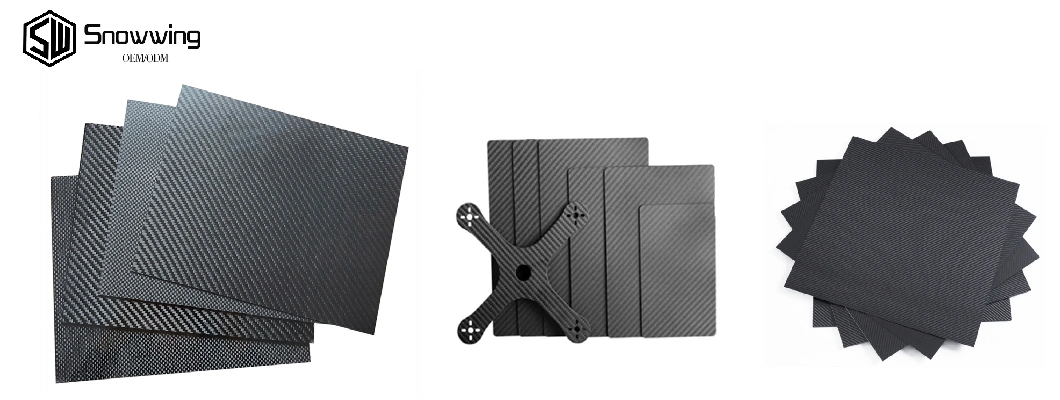

Wholesale 1k 2k 3k customized different twill plain wave size carbon fiber sheet.| Name: | carbon fiber sheet |

| Material: | High-end imported raw materials |

| Surface: | 3k twill,3k plain,bright,matte |

| Process: | layer |

Product Description

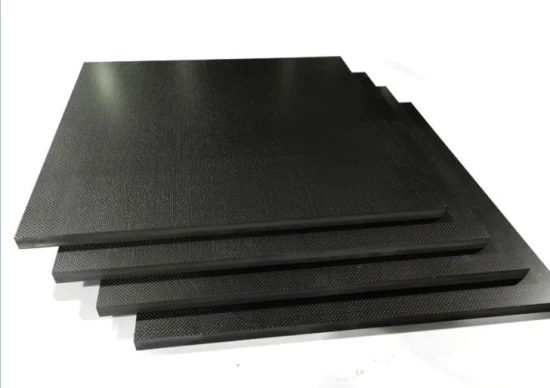

Surface: twill plain forged glossy/matte/50%glossy matteOperating temperature: below 200 degreeStrength: high pressure resistant/ high strengthWorkmanship: Molding processSize: Custom carbon fiber sheet

Our carbon fiber products can be customized with a variety of different surfaces to meet a variety of usage requirements.

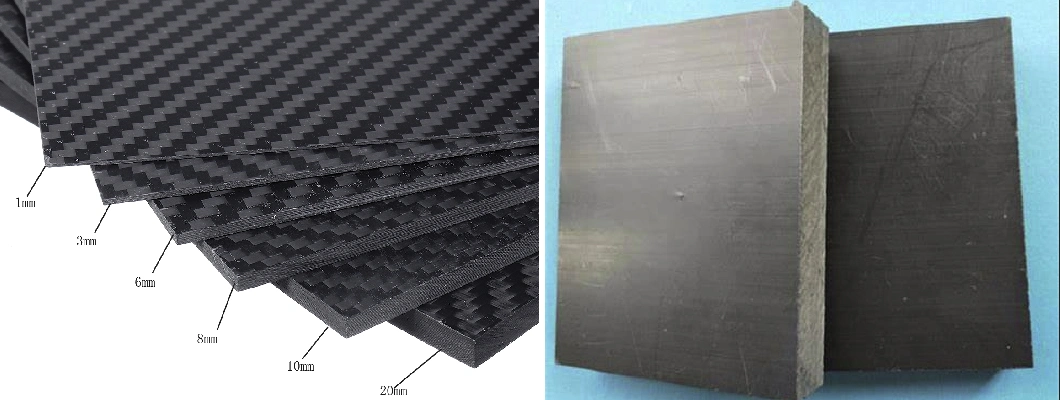

Our pure carbon sheet Other fake carbon sheets

| Carbon fiber products are made by laying carbon fiber cloth,and the edges show layers of carbon fiber texture, which is also a feature to identify whether it is carbon fiber. | The cross-section is cluttered and random,a kind of polymer made of plastic or other materials that doesn't hold as well as realcarbon fiber at the same thickness |

Product display

Size customization

| 300*200*1 | 400*500*1 | 500*700*1 | 600*700*2 | 700*600*2 |

| 300*200*2 | 400*500*2 | 500*700*2 | 600*700*3 | 700*600*3 |

| 300*300*3 | 400*500*3 | 500*700*3 | 600*700*4 | 700*600*4 |

| 300*400*1 | 400*500*4 | 500*700*4 | 700*400*1 | 800*400*1 |

| 300*400*2 | 500*500*1 | 600*400*2 | 700*400*3 | 800*400*3 |

| 400*400*1 | 500*500*3 | 600*400*3 | 700*400*4 | 800*400*4 |

| 400*400*2 | 500*500*4 | 600*400*4 | 700*500*1 | 800*500*1 |

| 400*400*3 | 500*600*1 | 600*400*5 | 700*500*2 | 800*500*2 |

| 400*400*4 | 500*600*2 | 600*500*2 | 700*500*3 | 800*500*3 |

| 400*400*5 | 500*600*3 | 600*500*3 | 700*500*4 | 900*400*1 |

| 400*400*6 | 500*600*4 | 600*500*4 | 700*500*5 | 1000*1000*2 |

| 400*400*7 | 500*600*5 | 600*500*5 | 700*600*1 | 1000*1000*5 |

| If you do not need the size please contact us we can be customized according to your needs | ||||

| The maximum thickness of carbon sheet can be 500mm*9000mm without upper limit | ||||

| Contact us | ||||

Application scenarios

| Carbon fiber is lighter than other materials and can improve UAV flight time while maintaining the same strength and stiffness of the UAV body Carbon fiber materials can be molded by molding, autoclave curing molding and other processes and simulation calculations toachieve a large area of integral molding, so that the UAV has a high wing-body fusion of the overall aerodynamic shape of the flying wing | Carbon fiber medical bed plateDue to its outstanding mechanical properties, specific strength and specific modulus compared with most structural materials have advantages, 10mm thick carbon fiber medical plate can bear 200kg weightBecause it is not metal material, and has good corrosion resistance, blood stains, alcohol, medicine and other substances drop, not have an impact on the surface |

| The relative density of carbon fiber is about 30% less than that of glass fiber, but the compressive strength is about 40%, andthe strain rate is 3-8 times higher. Using carbon fiber for large and medium-sized wind turbine blades can make full use of its advantages of light elastic cotton.The same leaf is 34M long, the quality of glass fiber improved alkyd resin is 5800kgthe quality of glass fiber improved epoxy resin glue is 5205kgthe quality of carbon fiber improved epoxy resin glue is only 3805kg. | Carbon fiber material has been used as one of the important materials in the production of more and more industrial machinery. Its special lightweight material performance can maintain almost zero coefficient of thermal expansion in the working environment with large temperature difference, and at the same time can maintain longer running time. Fatigue resistance and long service life, Fundamentally reduce the cost of manual maintenance, so that the intelligent level of mechanical equipment can be perfectly displayed |

Our team

We are a professional chinese manufacturer of FRP profiles.and also carbon fiber products for more than 10 years! we produce all type carbon fiber tubes,panel,bars,rods,CNC sheet Etc excellent properties include: corrosion resistance /lightness /good toughness If you want order our products, please include ID, OD, length, dimensional tolerances, quantity, structural requirements, surface finish, surface pattern, material (if you know), temperature requirements, pocesing technology etc.

With these items as the starting point, we can usually very quickly put together a quotation to help you get your project from idea to reality. pls click!Contact usWe have a professional R & D team and advanced production technology.It's a very reliable factory.

Buyer's praise

FAQ

1. Could I have prices of your products?

Welcome. Send your inquiry details below. Click "Send" now! You will get our reply in 24 hours

2. Are you trading company of factory?

We are manufacturer with over 20 years' experience in making tubes, you will get top quality products and services.

3. What's the lead time for regular order?

14-21 days for order quantity lower than 6000pcs; For more quantity, usually 30 days.

4. Can I get a discount?

Yes, for the order quantity more than 500 pcs, please contact us to get the best price.

5. Do you inspect the finished products?

Yes, each step of production and finished products will be came out inspection by QC department before shipping.