Polyester, Fiberglass, Aramid/Nomex, PPS, P84, PTFE Filter Sock Dust Collector Filter Bags

Basic Info

| Model NO. | PPS-550-1 |

| Gram Weight | 450GSM~550GSM |

| Structure | Yarn Form |

| Acid Resistance | Excellent |

| Alkali Resistance | Excellent |

| Anti-Abrasion | Excellent |

| The Stability of Water Solution | Excellent |

| Transport Package | Plastic Film |

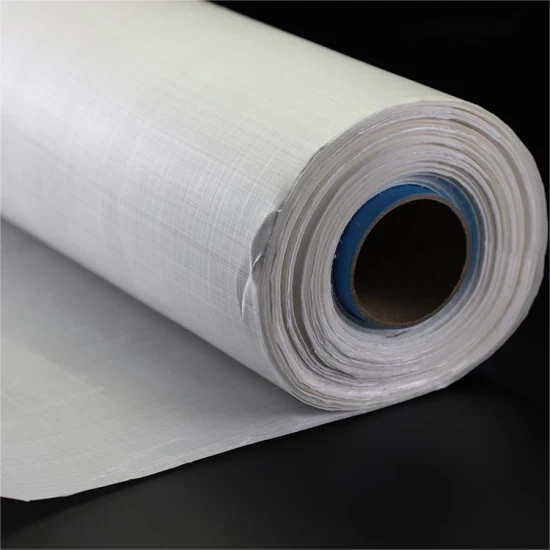

| Specification | 50m/roll |

| Trademark | Filter |

| Origin | China |

| Production Capacity | 1, 000, 000square meter |

Product Description

Polyester ,Fiberglass ,Aramid/Nomex ,PPS ,P84 ,PTFE Filter Sock Dust Collector Filter Bags

Description:

PPS filter bags are used for higher temperature applications with a maximum continuous operating temperature of 160ºC.

PPS filter bags raw material is made of Japan Toray PPS high quality fiber and produced by Germany equipment to loosening, needle punching.

Technical Specification:

| Fibre | PPS |

| Scrim | PPS |

| Weight(G/M2) | 500~550 |

| Thickness (mm) | 2.2 |

| Width (mm) | ≤ 2.2 |

| Length | 50m/roll |

| Finish treatment | Singeing, Calendering,oil&water repellent or with PTFE membrane treatment. |

| Air permeability (L/dm2/min): | 130 |

| Tensile strength (N/5× 20cm) | Warp:>1200 Weft:>1300 |

| Tensile elongation (%): | Warp:<30 Weft:<30 |

| Temperature (ºC): | Continue: 150 Instant: 192 |

| Anti-acid | Excellent |

| Anti-alkali | Excellent |

| Anti-abrasion | Excellent |

| Hydrolytic stability | Excellent |

Our company can provide different kinds of PPS filter bags according to the customer's demands as follow:

1. PPS filter bags

2. PPS water and oil repellent filter bags

3. PPS+PTFE scrim filter bags

4. PPS+PTFE blending filter bags

5. 30%PPS,70%PTFE filter bags

6. 50%PPS,50%PTFE filter bags

7. 70%PPS,30%PTFE filter bags

Applications:

Coal - Fired Boilers bag houses Calciners / Catalysts.

Municipal Solid Waste Boilers and Waste incinerator.

Electric power plant Electrolysis and other Specialty membranes.

Waste to energy Iron and non ferrous Metal Industry.

Features:

1.High efficient filtration level.

2.Depth type filtration.

3.Wide range of chemically compatible media.

4.High temperature resistance.

5.High flow efficiency.

6.High air to cloth ratio.

7.Various coatings are available.

Making method:

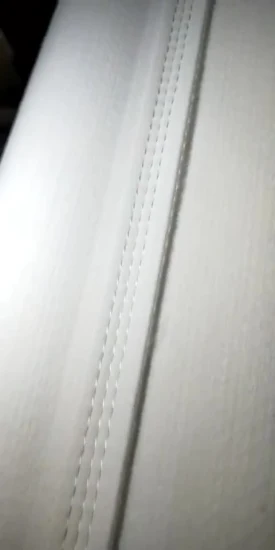

Our bags are sewn with 3 - needle chain stitch to ensure seam integrity. Top constructions consist of snap band, flange top, ring top, soft cuffs or raw edge. Bottom removal bags are constructed with a raw top or soft cuff. Top and bottom removal bag bottoms have disc bottoms that are sewn using an overlock (surge) stitch or lock stitch. A wear strip or custom skirts is attached to the bottom portion of the bag to prevent premature wear from bag-to-bag and bag-to-cage abrasion.

Packaging & Delivery:

Competitive Advantages:

1. 100% custom pass guaranteed.2. Our products have been exported to Germany, Norway, Poland, Finland, Spain, UK, France, Russia, USA, Brazil, Mexico, Australia, Japan, Korea, Thailand, Indonesia, Uruguay and many other countries.3. Flexible and Untraceable payment terms.4. Good after-sale service.

5. We offer high quality products at competitive price in quick delivery

Shipping Details:

SHIPPING (Normally arrive port time in working days) | ||||

| Destination | Express/Courier | SHIP BY SEA | SHIP BY AIR | SHIP BY EMS |

| DHL/FEDEX/UPS/TNT | ||||

| North America | 3~7 days | 15~24 days | 5~7 days | 10~12 days |

| South America | 3~7 days | 15~25 days | 5~7 days | 10~12 days |

| European Countries | 3~7 days | 20~30 days | 5~7 days | 10~12 days |

| Africa Countries | 3~7 days | 40~50 days | 5~7 days | 10~12 days |

| The Middle East | 3~7 days | 15~25 days | 5~7 days | 10~12 days |

| Australia | 3~7 days | 10~15 days | 5~7 days | 10~12 days |