Plastic Block Wear-Resisting Polyethylene UHMWPE Sheet for Machine Parts

Basic Info

| Size | Any Size Customer-Made |

| Transport Package | 50kgs/Carton |

| Specification | customized |

| Trademark | Customer required |

| Origin | Made in China |

| HS Code | 3920109090 |

| Production Capacity | 100000PCS Per Days |

Product Description

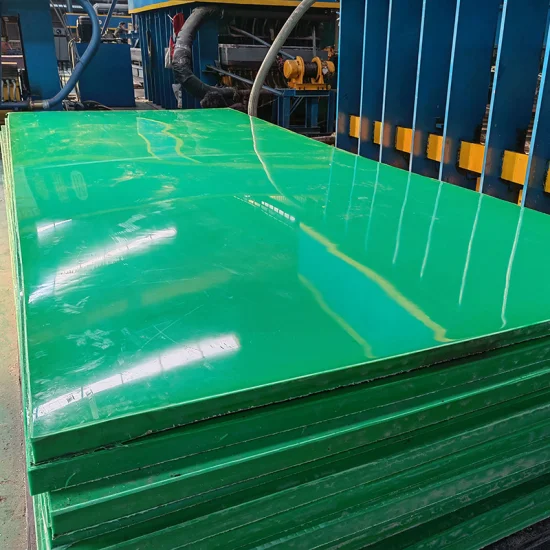

HDPE Block

Thickness:1mm-400mm

SIZE: customer-made

Color: Black, White, Yellow, Green, Blue etc.

High Density Polyethylene (HDPE) sheet is extremely strong against impact, abrasion resistant, and exhibits a low coefficient of friction. The material is also moisture, stain, and odor resistant, and is FDA approved for use in the food processing industry (mainly for cutting boards). The material's durability makes it a perfect match for a variety of applications such as water tanks, chute linings, bottle/bottle cap production and numerous other industrial uses. Borated HDPE offers radiation protection in nuclear facility applications.

Characteristics

no water absorption

Non-Toxic

Corrosion resistant

Abrasion and impact resistant

Wear Resistant

Application

Mechanically ground HDPE resins are used to rotationally mold large, complex shaped products such as fuel tanks, trash containers, dump carts, pallets, agricultural tanks, highway barriers and water and waste tanks for RVs. Additionally, HDPE sheet is often extruded with a pebble finish and is used as a cutting board in a variety of industry markets such as meat packing, butchering, and more.

more.

| Item | RESULT | UNIT |

| Mechanical properties | ||

| Modulus of elasticity | 1000 | MPa |

| Modulus of elasticity | 1000 - 1400 | MPa |

| Tensile strength at yield | 25 | MPa |

| Impact strength (Charpy) | 140 | Kj/m 2 |

| Notched Impact stren. (Charpy) | No break | Kj/m 2 |

| Ball indentation hardness | 50 | MPa |

| Creep rupture strength | 12,50 | MPa |

| Time yield limit | 3 | MPa |

| Coefficient of friction | 0,29 | ------ |

| Thermal properties | ||

| Glass transition temperature | -95 | °C |

| Crystalline melting point | 130 | °C |

| Service temperature | 90 | °C |

| Service temperature | 80 | °C |

| Thermal expansion | 13 - 15 | 10-5K-1 |

| Specific heat | 1,70 - 2,00 | J/(g+K) |

| Thermal conductivity | 0,35 - 0,43 | W/(K+m) |

| Heat distorsion temperature | 42 - 49 | °C |

| Heat distorsion temperature | 70 - 85 | °C |

1.

Q: What color can you make?

A: Usually we can make the regular color, like green, blue, black, yellow, grey and so on. Or you can offer the pantone color number for reference to produce.

2

Q: What is your MOQ?

A: It depends on the drawing.

3.

Q: What is your delivery time?

A: It depends on the volume, usually it is about 7 days.

4.

Q: How can I get a sample?

A: Small size of sample are free, you only need to pay for the shipping cost, or you can provide your UPS, DHL, Fedex, TNT courier account to us. Customized size of sample should be charged.

5.

Q: What is your payment ?

A:30% T/T in advance, balance before shipment. Other terms negotiable.