High Tensil Streght UHMWPE Fabric Anti Corrosion Wearing Resisting

Basic Info

| Color | White |

| Function | High Strength Fiber |

| Material | UHMWPE |

| Width | Customized |

| Structure | -(CH2-CH2)- |

| Transport Package | Carton |

| Specification | 80/130/160g/m2 |

| Trademark | utek |

| Origin | China |

| HS Code | 5603 |

| Production Capacity | 1000000m2/Month |

Product Description

400D, 600D and 800D ultra-high molecular weight polyethylene fibers are often developed for cut resistant gloves. Although special coating technologies often involve spandex, chinlon, dacron, glass fiber and stainless steel, none of the gloves are as soft as those made of UHMWPE fibers turned into a knit yarn for cut resistant gloves. Soft and convenient, the UHMWPE gloves meet GA 614-2006 standards, (making them ideal cut resistant gloves for use by police) and EN3888 standards. We have a complete series of gloves available to meet your requirements for cut resistant, soft and wearable gloves, as well as other high end requirements.

Cut resistant gloves made of aramid fiver are heavy and uncomfortable, gloves made of glass fibers are lightweight, but not very durable or comfortable, and gloves made of steel wires are highly uncomfortable due to the rigidity of the wire. However, cut resistant gloves made of UHMWPE fiber have outstanding protection and comfort properties, making them increasingly popular. These UHMWPE gloves effectively protect police officers and other law enforcement officials (security guards and other law enforcement agents) from wounds caused by a sharp instruments.

UHMWPE cut resistant gloves are thinner, lighter and more tactile than gloves made of other materials (such as aramid fiber), making them comfortable to wear, with an excellent abrasion resistance and durability, protecting users from harm even in harsh conditions. These gloves also are breathable, cool and comfortable to the touch, reusable and easy to clean. In addition, they provide an abrasion resistance 50 times greater than that of aramids and a better cut resistance than leather or cotton. Due to these excellent features, Our cut resistant gloves are used in a wide range of handling and carrying applications, including glass handling, metal fabrication, steel manufacturing, security forces and more.

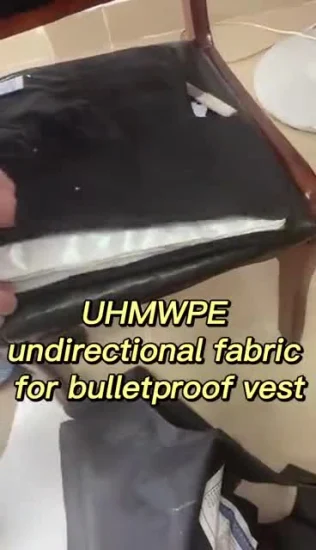

Applications1.Life protection:body armor,bomb suppression blanket,bulletproof helmet,bulletproof plate,armored vehicle,anti-explosion yacht.

2.Industry Application:cut-resistant glove,lifting rope,wind power cable,safety harness.3.Civil use:cut-resistant fabric,cooling fabric,cycling clothes,climbing rope,parachute rope,sailing rope,kite line.

4.Fishery:commercial fishing net,marine aquaculture net,fishing line.5.Offshore:drilling platform,anchou cable,towrope,mooring rope,lifting rope.6.Aerospace:re-entry module of spacecraft recovery system,aviation cage,

Properties

| Products | Features | Applications |

| 400D-UHMWPE Fiber | Tenacity≥30cN/dtex | Cut-resistant gloves Level 3/5(EN388) |

| Covered yarn | soft, anti-static, low cost, etc | Cut-resistant gloves Level 3/5(EN388) |

covered yarn uses the patented TYZ fiber as its core, ranging in percentage from 30-70%, then wrapped in various yarns and fibers, such as spandex, nylon, polyester, fiberglass, stainless steel wires or more, making it an ideal choice for cut resistant gloves.

Covered Yarn

High strength covered yarn is made of Doyentrontex fiber, using a special coating technology involving spandex, chinlon, dacron, glass fibers or stainless steel wires. This yarn is widely used to make cut resistant products, like our cut resistant gloves.

Composition of Covered Yarn:

PE+ dacron: hard hand feel good compatibility and low cost PE+ nylon: comfortable hand feel, bad compatibility and high cost

PE+ glass fiber: comfortable hand feel, good cut resistant property

PE+ stainless steel wire: hard hand feel with good cut resistant property.

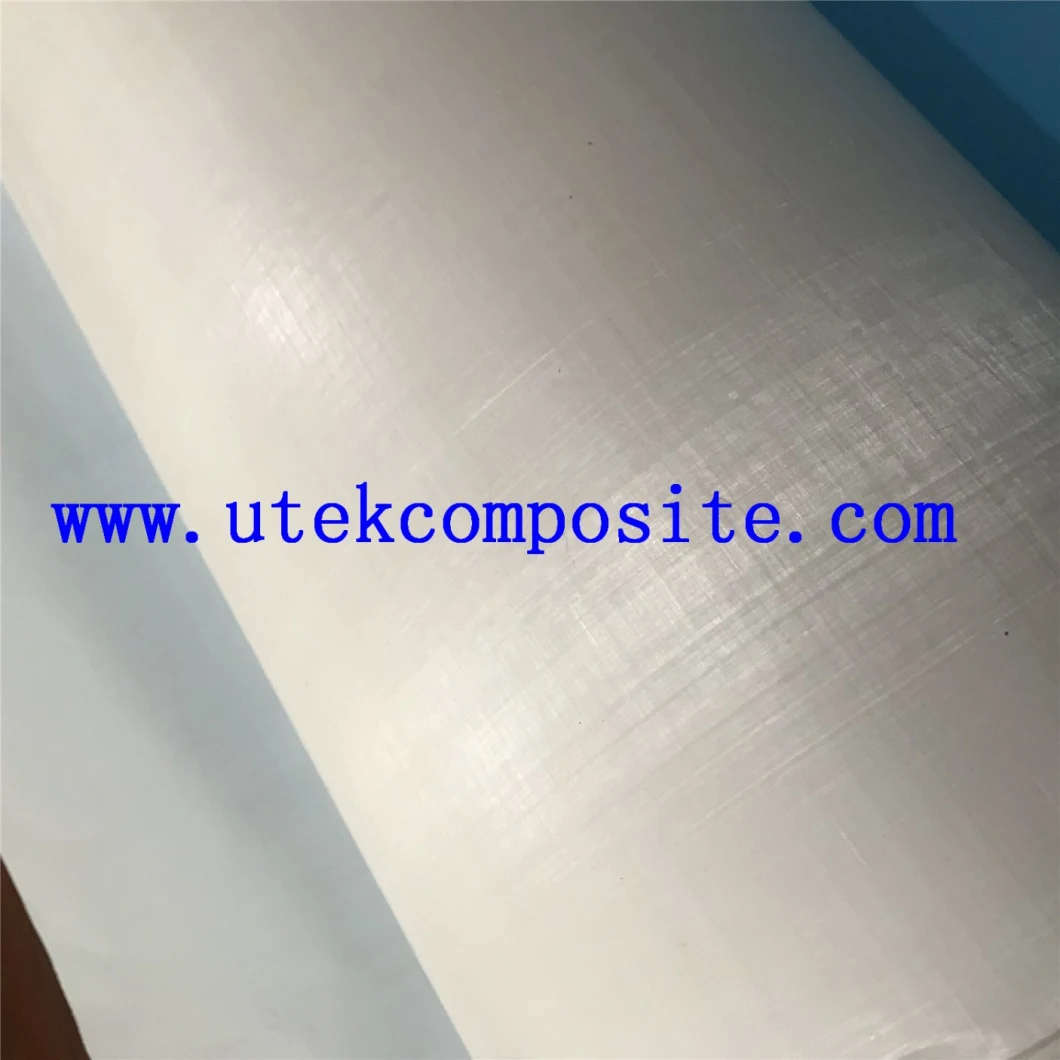

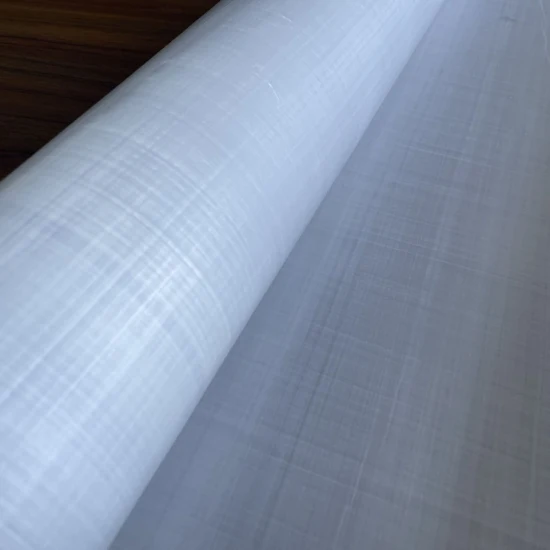

Detailed Photos