China Professional Plastic Sheet System for UHMWPE Panels

UHMWPE Fender/Plates/Sheets Ultra-high molecular weight polyethylene (UHMWPE) is a kind of engineering thermoplastics wi

Basic Info

| Material | UHMWPE |

| Kind | Engineering Plastic Sheet |

| Water Absorption | 0.2%~0.4% |

| Contraction Percentage | 0.4%~1.4% |

| Tensile Strength | 3.9MPa |

| Anti-Aging | 50 Years |

| Type | Thermosetting Plastic Pipe |

| Color | White, Black, Yellow, Red, Blue |

| Style | Solid |

| Usage | Water Supply |

| Transport Package | Exported Standard |

| Specification | ISO9001, BV, CCS, ABS |

| Trademark | DMC |

| Origin | Shanghai, China |

| Production Capacity | 100000 PCS/Year |

Product Description

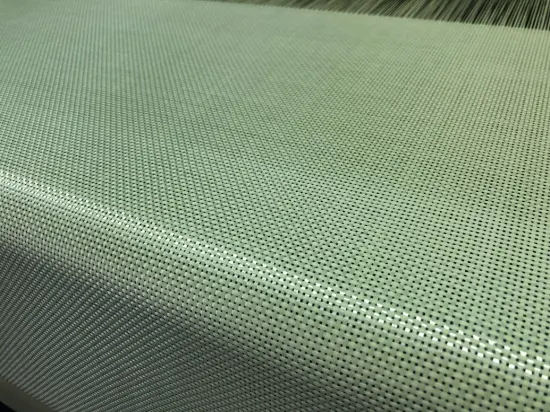

UHMWPE Fender/Plates/SheetsUltra-high molecular weight polyethylene (UHMWPE) is a kind of engineering thermoplastics with more than 3 million viscosity-average molecular weight. It differs from PE standard grades in its very high degree of polymerization.

Ultra-high molecular weight polyethylene sheet has superior performance over conventional HDPE sheet such as very high wear resistance, impact resistance, intrinsically self-lubricating, anti-adhesion, low temperature resistance and excellent chemical resistance.

Properties comparisons of UHMWPE , HDPE and steel.

| Item | Test method | Unit | UHMWPE | HDPE | Steel |

| Density | ISO1183 | g/cm3 | 0.94 | 0.945 | 7.8 |

| Melting temperature | ISO11357 | °C | 136 | 129 | 1410 |

| Water absorption | ISO11359 | % | <0.01 | <0.01 | - |

| Coefficient of linear thermal expansion | ISO11359 | 10-4/°C | 1.5 | 1.2 | 0.17 |

| Heat deformation temperature | ISO75 | °C | 85 | 71 | 1230 |

| Yield strength | ISO527 | Mpa | ≥22 | 20 | ≥245 |

| Tensile elongation | ISO527 | % | ≥250 | ≥350 | 20 |

| Gap beam impact strength | ISO179 | KJ/m2 | No break | <27 | No break |

| Rockwell hardness | ISO2039 | R | 40 | 33 | 45 |

| Friction coefficient | ISO8295 | - | 0.05 | 0.28 | 0.58 |

| Corrosion resistance | - | - | Excellent | Good | Bad |

Application

1. It can be use in Machinery industry, Food industry, Paper-making industry, Chemical Industrial, etc.

It is the best material used as bulk materials storage and transportation equipment lining, such as silos, flow ducts. It is widely used in electric power, steel, coal industries etc.

2. It can be made with coal, cement, lime, slag, salt, cereals, powdered material hoppers, silos, chute lining. Because of its excellent abrasion resistance, self-lubricating and non-sticky, so that the powdery material for storage and transportation equipment, adhesion phenomenon does not occur, to ensure a stable transport.

3. This high wear plate installed applications to adapt to a variety of environmental conditions, can be designed to assemble the connection structure according to user requirements, ease of installation and maintenance. If the operating conditions are very difficult to install underground mine hopper, chute applications, metallurgical industry, feed hopper, etc., can solve the transportation process bonding and sealing material of this long-standing problem, to achieve safe, efficient and normal production.

4. It used in transportation of liquid, solid, solid-liquid mixture in the funnel, drain tank flap, scraper conveyor chute mining, coal preparation plant, metallurgical industry, power plant, shipbuilding and other sectors, sieve jigger, flotation machine liner, liner board cargo vessels, large slide, tub, dump trucks and other cars lining of wear and corrosion applications

Send to us